Price:

Buy

While most of the HiFi racks adopt the so called soft-sweeping approach, there are not many designs which apply different materials to adsorb vibration from the floor. R1 Low Resonant Rack is one of those in which we spent years to research and develop.

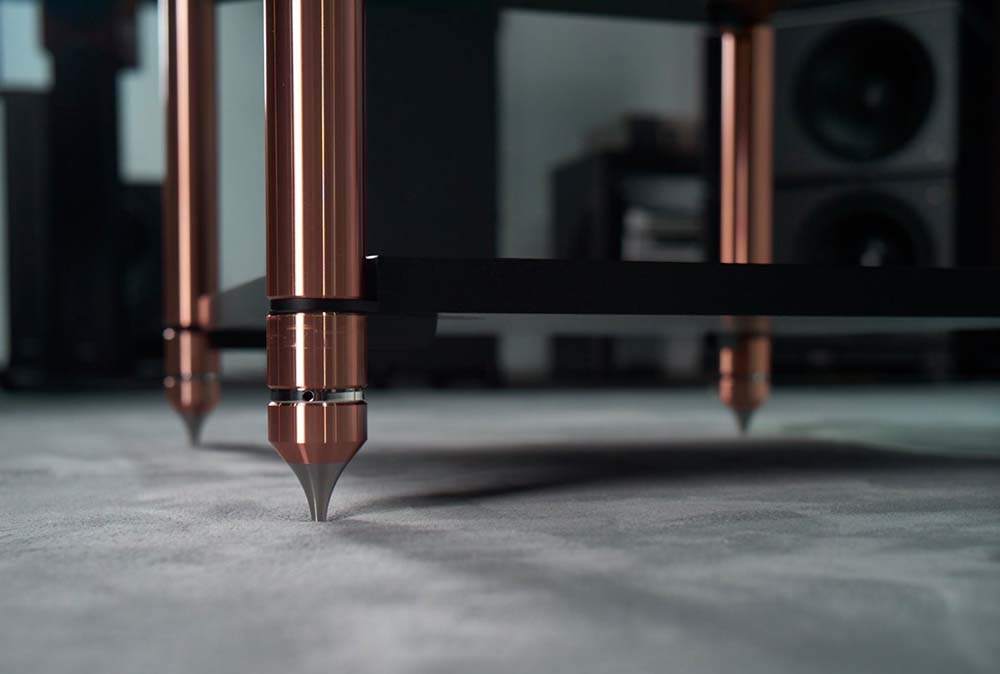

● Sharing the same pillar and footer architecture as R2, R1 demonstrates excellent isolation charachteristics to shield audio equipment from vibrations from the ground.

● Patent pending supporting architecture prevents the residual vertical vibrations of the pillars from being transmitted to the shelf boards, revealing the inner detail of the music.

● 25mm aerospace grade aluminium alloy combined with the supporting parts provides a sturdy, low-resonance equipment surpasses that of all similar products in the market.

● One can increase the number of shelves without the need to replace the bolts and footers, making the upgrade simple and straightforward.

● 25mm HDF shelf board is also available.

racks design is basically to help equipment achieve the best "zero vibration."

Most of these vibrations are actually small vibrations from the equipment itself. The most significant cause is the massive transformer and the CD Player rotating parts in the rear stage. Some are caused by too simple shells and poor shock-absorbing design.

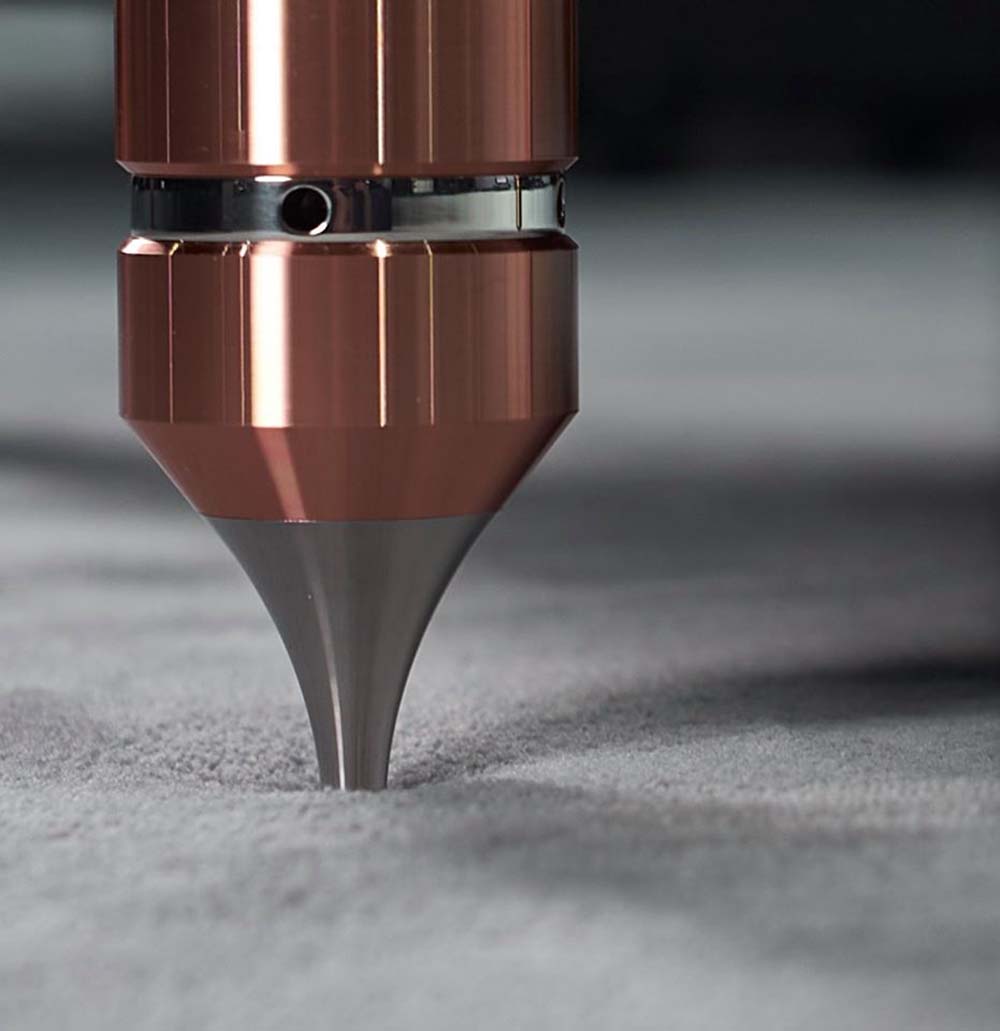

The shock-absorbing design concept of our R1 rack and M series chassis: First of all, from the design of the nail feet, through the cooperation between different metal materials, let the ground shake first from the hard stainless steel material. It transmitted to the buffer structure with damping materials, which allows most of the ground vibrations to be converted into thermal energy and digested by the aluminum alloy structure. The patented design of the support enables no metal contact between the nail feet and the equipment layer, which once again prevents the remaining small ground vibrations from being transmitted to the equipment layer. If the customer is using smooth ground, then we have a special nail pad made of bronze alloy and damping material. First, the rigid vibration unique to the hard ground is eliminated, and then the stainless steel nail feet are used to continue to consume the remaining energy.

The function of the equipment layer board is to provide the equipment with a sturdy platform that can precisely adjust the level and consume its own vibration energy. Our approach is to produce a completely flat aluminum alloy platform through a precision and high-precision machining center with a flatness of 0.02 mm. The raw material of this aluminum profile must be imported material that is pre-stressed in advance. Specially designed bronze alloy nail pads are provided for audio equipment to further suppress self-vibration. Of course, you can also choose our unique sandwich structure laminate to provide better composite shock absorption.

Of course, you can also directly add our R1 aluminum alloy laminate to the racks you already use. In this way, it will have a pronounced effect in isolating the ground vibration and resisting the wave of the equipment itself. It is suitable for customers who don't want to spend too much money but want to improve the clarity of sound, localization of sound field, and low- frequency drive.